ABOUT our technology

Ash Pond beneficiation

innovation with flexibility

modularity and mobility

FLexibile

What sets us apart is the system's portability; it can be efficiently transported to another site as needed.

capabile

Each modular unit is capable of operation within an area approximately the size of a football field.

environmental

Each unit is capable of producing over 100,000 metric tons of fly ash annually with no additional waste stream.

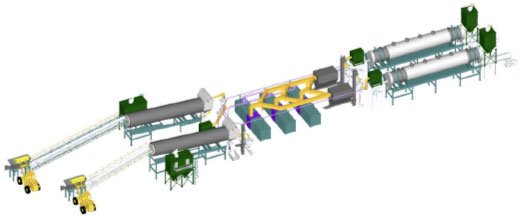

WORKING PROCESS

How To Get Better Results

Ash-TEK redefines ash pond remediation. Minimize your carbon footprint.

Step

01

DRYING

Wet ash undergoes a crucial drying phase in a large industrial dryer. This initial step is essential for preparing the material for subsequent handling and processing.

Step

02

Classifying

Through a combination of air and mechanical classification systems, our process efficiently separates fine, coarse, and bottom ash, ensuring precision in material handling.

Step

03

Fracturing

We utilize an innovative system that employs a unique combination of pressure, vortex boundary layer differentials, and acoustic forces to fracture and shear the coarse fraction of the ash. This process not only reduces particle sizes but also exposes oxidative surfaces that have been sheltered in ponds for an extended period. The resulting angular shape of the particles enhances reactivity and strength activity.

Step

04

carbon reduction

In this critical step, carbon in the material is sublimated, contaminants like heavy metals are removed, and oxidized surfaces are re-activated. This ensures the final product meets the highest quality standards.